Description

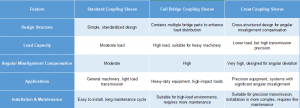

Standard Coupling Sleeve

A standard coupling sleeve is a commonly used mechanical connecting component, typically made of high-strength steel or alloy materials. It is used to connect two shafts to transmit torque and compensate for misalignment between the shafts. Standard coupling sleeves are suitable for applications with relatively small axial displacement and are widely used in various mechanical transmission systems.

Features:

- High-strength, wear-resistant materials

- Standardized dimensions for easy compatibility with other components

- Suitable for applications with moderate load and speed

Full Bridge Coupling Sleeve

A full bridge coupling sleeve is a coupling designed with multiple bridge-shaped connecting parts to handle higher load-bearing capacities. It is suitable for high-load, heavy-duty equipment and can better distribute torque, as well as accommodate larger axial, radial, and angular misalignments.

Features:

- High load-bearing capacity

- Better torque distribution

- Suitable for heavy-duty equipment and high-impact loads

- Enhanced axial, radial, and angular misalignment compensation

Cross Coupling Sleeve

A cross coupling sleeve features a specialized design with a cross structure that provides superior angular misalignment compensation. This type of coupling is ideal for applications requiring large angular misalignment, particularly in precision transmission or complex mechanical systems. It effectively reduces damage and energy loss caused by angular deviations.

Features:

- Optimized angular misalignment compensation

- Suitable for applications with significant angular misalignment

- Provides higher transmission accuracy

- Commonly used in precision machinery or systems with frequent rotation

🔹Key Differences Between the Three:

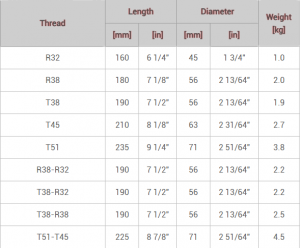

🔹Product Specification

(Can’t find the right size? Please contact us!)